ESG

Product Traceability Management

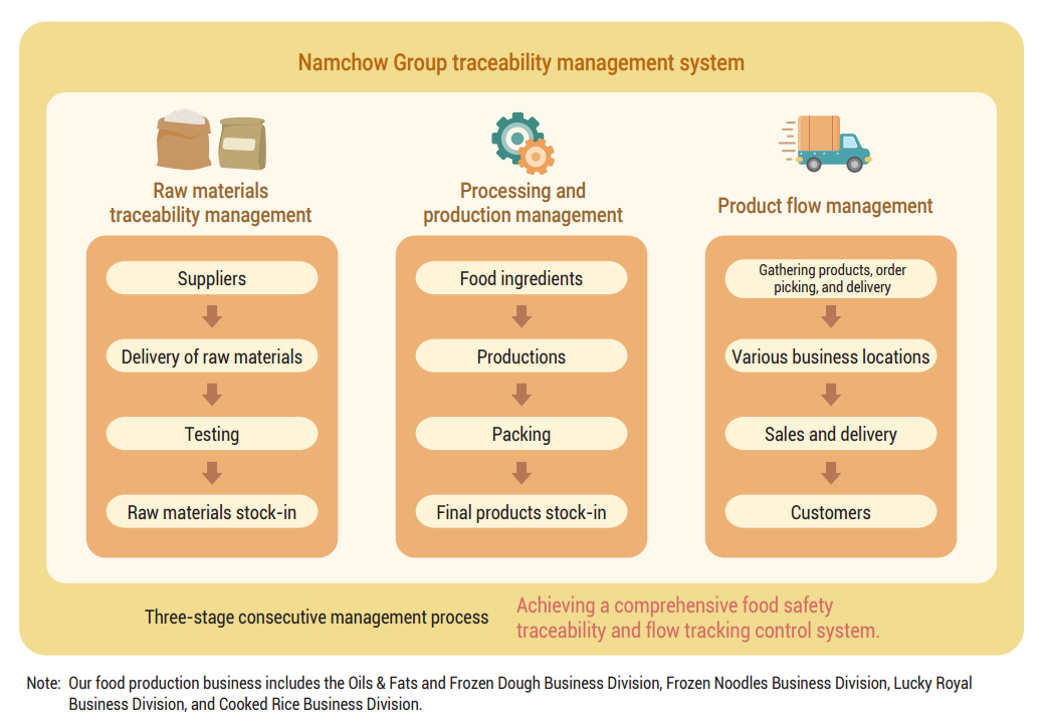

The diversity, professionalism, and division of labor in the food industry have resulted in today’s very complex food chain. Local and overseas manufacturers alike have to evaluate and consider sources, quality and safety of raw materials or products. As a result, information regarding the origin of raw materials or products is increasingly important to food manufacturers. We have therefore introduced a food resume traceability system that integrates the public cloud of the food registration platform with the private cloud of the traceability system. Together, they provide the public with fast and accurate product information. In 2023, there were no recalls or product withdrawals due to food safety issues in any region.

Taiwan region

■ Manufacturing business

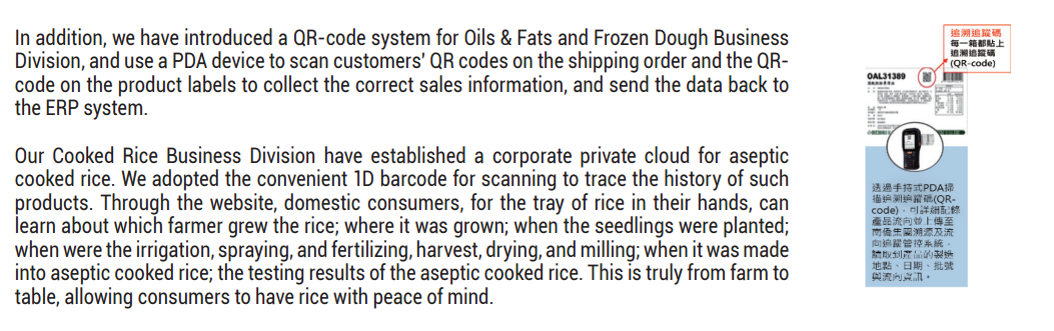

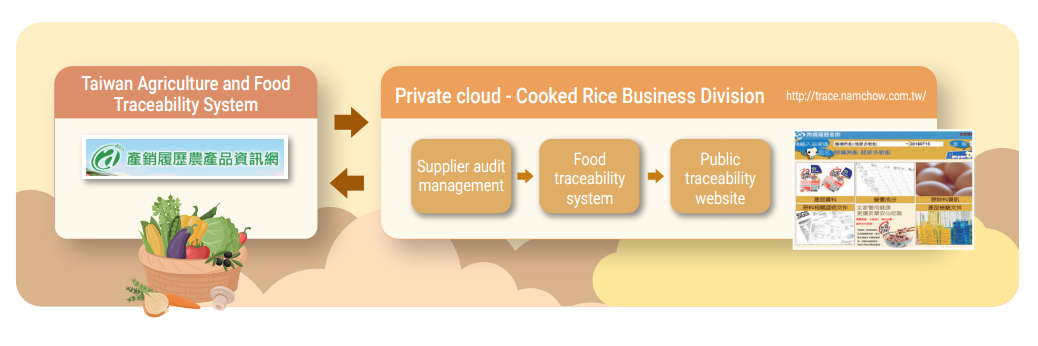

Our food production businesses in Taiwan have registered information designated by the government on the Fadenbook—FDA Registration in accordance with the laws, including basic information on the food business, scope of business, and factory information. Information including the raw material purchase order number, raw material stock-in date, production order number, product expiry date, and shipping order number is used as the concatenated code for product traceability. Purchasing, manufacturing, and sales data are entered into ERP to achieve 100% traceability of products’ raw materials and distribution. We simulate product recall once a year to verify the effectiveness of the product traceability system. The ERP traceability data will be integrated into and uploaded to the public cloud platform of Namchow Group for convenient inquiry on the platform. Before the 10th of each month, we upload the product traceability data of the previous month to the government’s “food cloud” (Food traceability system - Ftracebook), and use e-invoice to help fulfill the purpose of the government’s electronic management of food traceability.

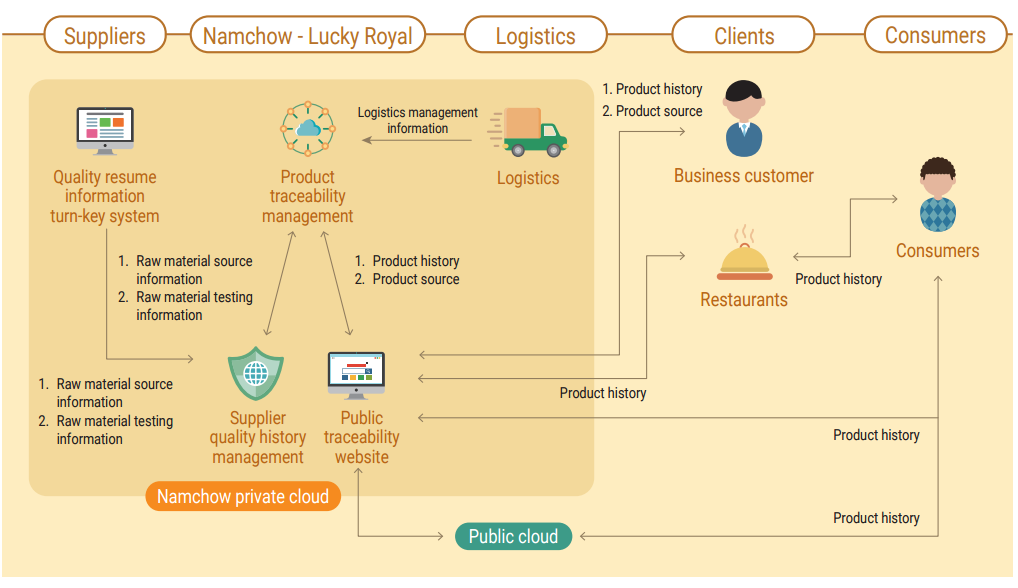

As for our Lucky Royal Division, it has implemented the Oracle electronic system to monitor the food traceability management system so that everything from the management of raw materials and food additives to the tracking of product flow is within its grasp. When combined with the Duroyal Ice Cream Business private cloud, consumers are given easy access to accurate information on all products offered.

■ Detergents Business

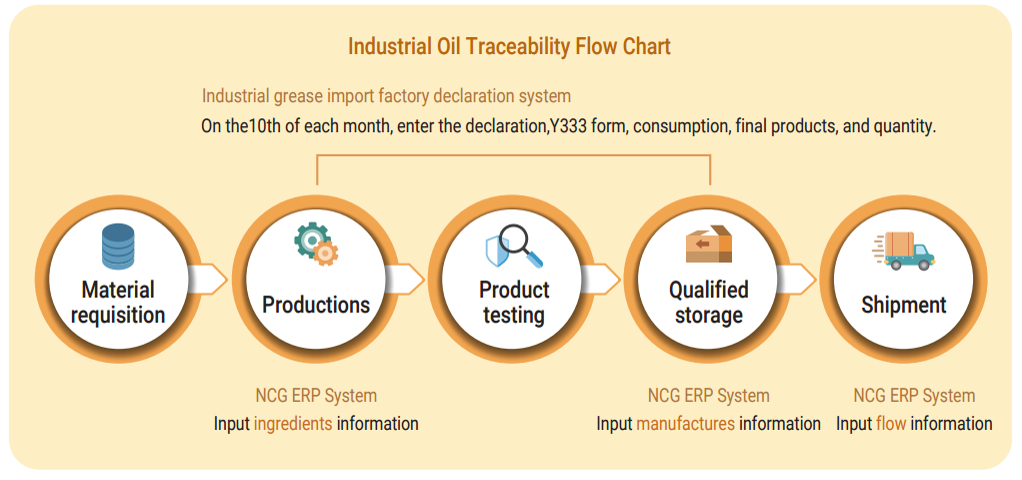

Namchow Detergent has set up a database to track the distribution of all imported industrial oils as part of the imported general industrial oil & fat factory reporting system required by law. The Taoyuan Factory now uploads 100% of its traceability data for products made from imported industrial oil to the reporting system.

■ Gastronomy Business Division

In consideration of food safety risks associated with various ingredients, and in accordance with the guidelines of the “Raw Material Usage and Supplier Management Procedures,” suppliers are required to fill out a “Raw Material Survey sheet.” Additionally, they are requested to provide relevant sanitary testing or packaging certification to confirm the source of the materials. In 2023, 68% of the gastronomy procurement amount can be traced back to its source.

Mainland China

■ Manufacturing business

Products produced at the Tianjin, Shanghai, and Guangzhou factories have adopted the following traceability management and control information in accordance with the Food Safety Law and the production control requirements of customers and the enterprise itself. This ensures the rapid tracing of target history, application of location. In addition, each factory conducts at least one simulated traceability/recall exercise each year to verify the 100% traceability of all products and raw materials.

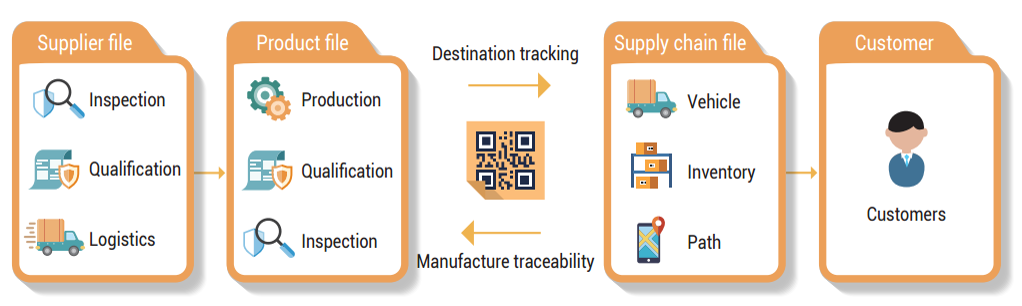

The traceability and recall procedures are used to control and verify product traceability. First, proper labeling and records enable the rapid and effective identification, quarantine, and tracking of affected products. The advanced Electronic Resource Planning (ERP) system, allows the company to strictly control and record raw material access, storage, and transport information according to the production formula, process, and quality requirements throughout the whole production process. Information queries and traceability management can then be carried out more quickly and accurately.

The ESC (Electronic Supervision Code) two-dimensional code encoding and the WMS (Warehouse Management System) are two mature and operational systems. A 2D code is printed on each product carton and another 2D code is automatically generated for each pallet. The 2D codes of the pallets and the cartons are then linked to each other, making it possible to query the product warehouse and shipping information through the 2D code. In the future, users can scan the 2D code with their mobile phones to get more product information.

Each factory’s production lines conducted simulated traceability and recall drills, primarily using a combination of ERP, WMS, and paper-based records for the exercise.

The goal was to strengthen the management of food traceability information, practice production operator responsibility, improve the effectiveness of food safety supervision, as well as protect the public’s physical health and consumers’ right to know.

The Shanghai factory follows the regulations outlined in the “Shanghai Food Safety Information Traceability Management Measures.” These regulations require the implementation of information traceability management for eleven major categories of food and edible agricultural products within the administrative area of Shanghai. This management covers the entire process, including production (including cultivation, breeding, and processing), distribution (including sales, storage, and transportation), and catering services. Specifically, the meat product division of the Shanghai factory has established a smart traceability system recently in accordance with the “Guidance on Promoting the Smartization of Food Production Process Traceability System” and the “Three-Year Action Plan for Quality and Safety Improvement of Meat Products in Jinshan District.” This system enables real-time information upload for various processes, including raw material procurement, inspection and receiving, production requisition, processing, product inspection, release, final product storage, and shipment. Additionally, it has successfully integrated with the government’s traceability platform, allowing for real-time access to traceability information with a single click.

To meet the Guangzhou city government’s basic traceability management requirements for food production enterprises, our Guangzhou factory has registered its basic information, raw/auxiliary materials, supplier profile, and product-related information with the “Guangzhou Food Production Process Monitoring Platform”.

■ Gastronomy Business Division

The purchasing department of BLN Restaurants & Caterings strictly follows the regulations of the “Food Safety Regulation of Shanghai”. Each restaurant maintains a ledger on food acceptance based on the template provided by the Shanghai Municipal Administration for Market Regulation. The ledger provides a faithful record of all traceability information from purchased food products. In 2023, 89.59% of raw materials for foods by value could be traced to their origin.

Thailand region

100% traceability is available for products manufactured by Namchow (Thailand) from raw materials to the final product or from final products to raw materials. Purchase order number, package label reference code, or the date of manufacture printed on the package can be used to trace products back to their raw materials as well as packaging. By establishing new product coding principles to facilitate document management and data storage within the ERP system, and by developing an annual product traceability testing plan, in 2023, 10 product traceability tests were conducted, and it was confirmed that 100% of the traced products were successfully completed.

Correct and Complete Product Information

To let consumers understand the basic information of products and ensure the proper disclosure of basic product information, the containers or outer packaging of all products, foods, and ingredients produced by each region are clearly and fully labeled in accordance with local regulations. In 2023, Namchow Group did not experience any legal violations related to food labeling and descriptions.

Taiwan region

Product conformity is checked by all relevant units before a new product is launched in the market. For example, R&D checks for compliance with national standards, the Food Safety Office reviews the ingredients and labeling, and Legal Affairs reviews the relevant laws to ensure compliance with Act Governing Food Safety and Sanitation and related regulations.

All product labeling adheres to Article 22 of the Act Governing Food Safety and Sanitation. The labeling for Oil & Fat products and the Frozen Dough Business Division currently provides an expanded list of all ingredients. As a result, customers receive full disclosure on product ingredients, nutritional content, allergens, and genetic modification information. All of the above information is labeled fully and clearly on the product packaging with no promotional messages or slogans added.

All takeaway by the gastronomy business are properly labeled in accordance with the regulations. In addition, the origins of ingredients are indicated on some menus to provide consumers with full disclosure so they can enjoy our products without fear.

Mainland China region

All business units in the Mainland China region adhere strictly to the "Pre-packaged Foods that are Directly/Indirectly Supplied to Consumers" labeling requirements of "GB 7718 Food Safety National Standards for General Rules for the Labeling of Prepackaged Food," "GB 28050 National Standard on Food Safety -- National Label Standards for Pre-packaged Food," and "GB 13432 China Food Safety National Standard for General Rules for the Labeling of Prepackaged Food for Special Dietary Uses." Such labels must contain food name, specifications, net content, date of manufacture, shelf life and storage conditions, implementation standards, place of origin, factory location, contact information, nutrition label, and allergens. Other information not marked on the label is noted in the manual or contract. All labels must be jointly reviewed by the Marketing Department, Legal Affairs Department, Quality Department, and R&D Department.

Thailand region

Namchow (Thailand) works closely with the customer on all of its products to provide correct product labeling information tailored to their sales region. Product labeling, therefore, conforms to national regulations or policies. Product labeling includes shelf life, product ingredients, storage recommendations, cooking instructions, importer’s name and address, legal and regulatory warnings and other food regulatory labels, and requires strict internal review and approval.