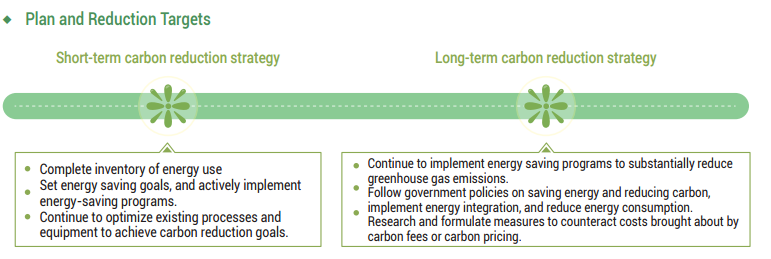

Namchow Group is committed to promoting energy conservation and emission reduction, continues to evaluate and introduces international management standards to improve energy management efficiency and climate resilience. In the mainland China and Thailand regions, our factories have established environmental management systems through ISO 14001 certification and third-party verification to comply with applicable laws, regulations, and other environmental requirements. We also adhere to the principles of ISO 14064-1 for greenhouse gas inventories, gradually conducting greenhouse gas emissions inventories and verifications in various regions. Carbon reduction targets will be set based on the inventory results. Starting from an inventory of energy consumption, we will plan a reduction plan, and evaluate and develop actions in multiple aspects to respond to climate change.

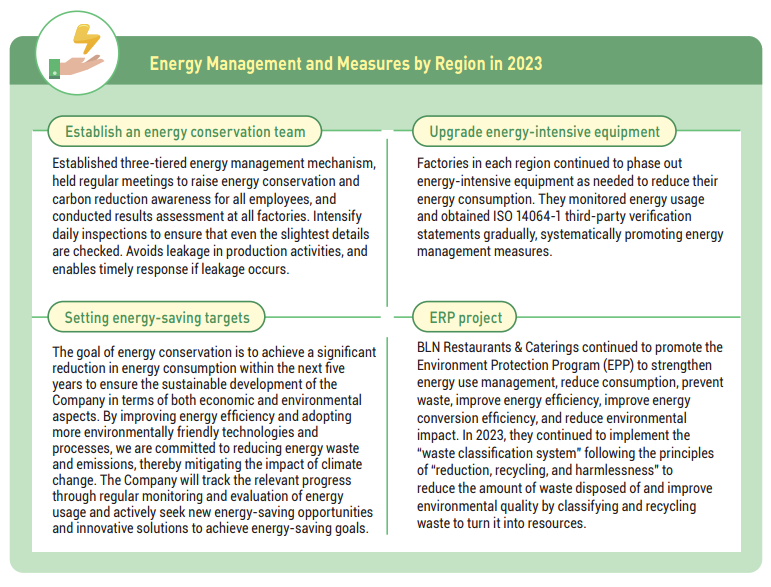

Energy consumption by Namchow Group consists mainly of purchased electricity, natural gas, and coal; to strengthen our energy management, we have organized an internal energy conservation task force to promote energy conservation measures that reduce consumption, prevent energy loss, and curb waste. We also developed energy efficiency indicators and targets in support of regional government energy and environmental policies, or by signing the "Annual Energy Conservation Target Responsibility Agreement Letter" in order to improve energy conservation, enhance energy conversion efficiency, and reduce our environmental impact.

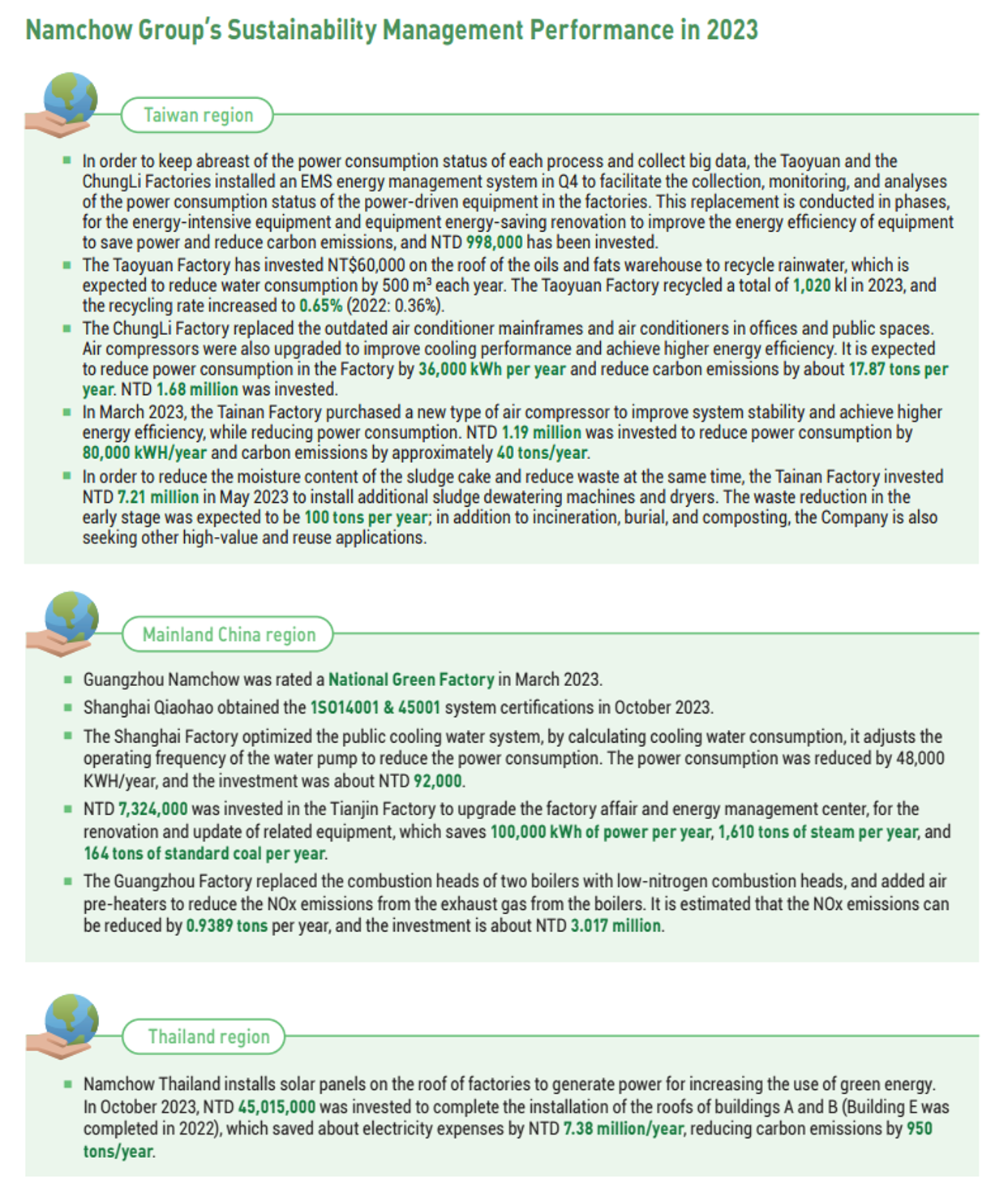

In 2023, each region continued with efforts to implement various energy management measures with the expectation of achieving energy-saving and emissions reduction results.

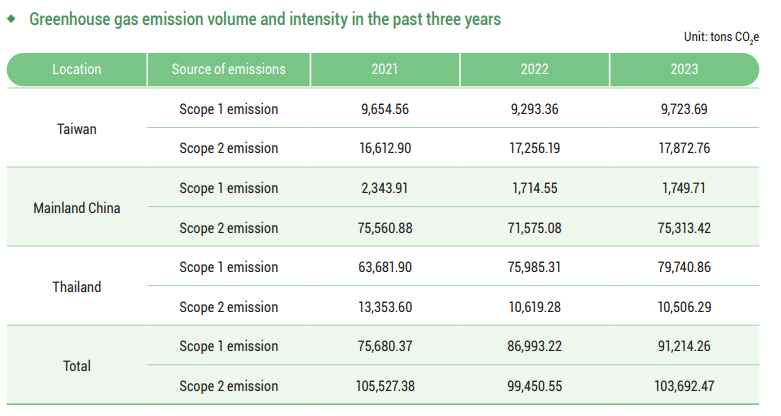

Greenhouse Gas Management

Most of the greenhouse gases emitted by Namchow Group are associated with energy consumption. Our current focus is therefore on the inventory of energy consumption. Each Factory has been authorized to manage their consumption levels

according to local regulations.

The changes in the global rainfall pattern, and the increased frequency of heavy rains and prolonged droughts in recent years have resulted in an unstable water supply, thereby increasing business risks. As food processing as Namchow Group’s main production model, clean and sanitary water resources and stable water supply are of significant importance to the Group. Therefore, water resources management plays a critical role in the Group’s sustainable development.

The water used in restaurants and food processing facilities in various regions, including Taiwan and mainland China, is sourced from disposable tap water provided by local governments or relevant authorities. The operational risk associated with water resources is relatively low. However, as part of corporate social responsibility, multiple water conservation measures are implemented to effectively manage water resources. In Thailand, treated water from deep bores is used. The use of groundwater may lead to ground subsidence and deplete underground aquifers, so water conservation and exploration of new sources of water supply are issues our business in Thailand will continue to face in the future.

In recent years, changes in rainfall patterns have occasionally led to water interruptions or restrictions, with an average duration of less than 24 hours. To address such situations, the ChungLi Factory in the Taiwan region has storage tanks and water towers with a capacity to supply the factory for three days or more, ensuring uninterrupted operations. Similarly, the Shanghai Qiaohao Factory in mainland China has a 650-cubic-meter emergency water tank in place to prevent accidents and reduce operational losses.

Due to greater differences in seasonal and regional rainfall in various regions, there is a possibility that drought may lead to water restrictions or reduced water supply. In addition to ongoing water conservation measures and wastewater treatment, each region conducts water use inventories using the World Resources Institute’s (WRI) water resource risk map to regularly assess the water risk levels of the areas where each production site is located and uses the results to develop water use improvement plans and water conservation plans.

In response to the global trend of green environmental protection, Namchow Group has incorporated the concept of circular economy into waste management. We modified our processes to reduce waste generated, and increased the recycling rate from processes to achieve the goal of reducing waste from the source.

Industrial waste generated by Namchow Group’s operating sites in each region is removed, treated, or recycled in accordance with local government regulations. Related information is also regularly declared through online reporting. In addition, the removal, disposal, and reuse of industrial waste are double-checked online within the prescribed deadline. Waste sorting, collection, storage, management, and disposal are enforced for effective waste control. The waste treatment by the Group’s operating sites in each region in compliance with the requirements of laws and regulations. They apply for discharge or treatment permits in accordance with the law and file reports to the competent authorities truthfully. At present, waste is mainly disposed of by external treatment companies.

The Taoyuan Factory collects statistics on the amount of waste generated in the factory every month to determine which factory activities generate the most waste and which types of waste have the greatest impact on the environment and health. Waste management optimization plans are then evaluated during the quarterly Occupational Safety and Health Committee meetings. In 2023, the policy of reuse of waste cooking oil was continued to reduce the waste generated during the production process.